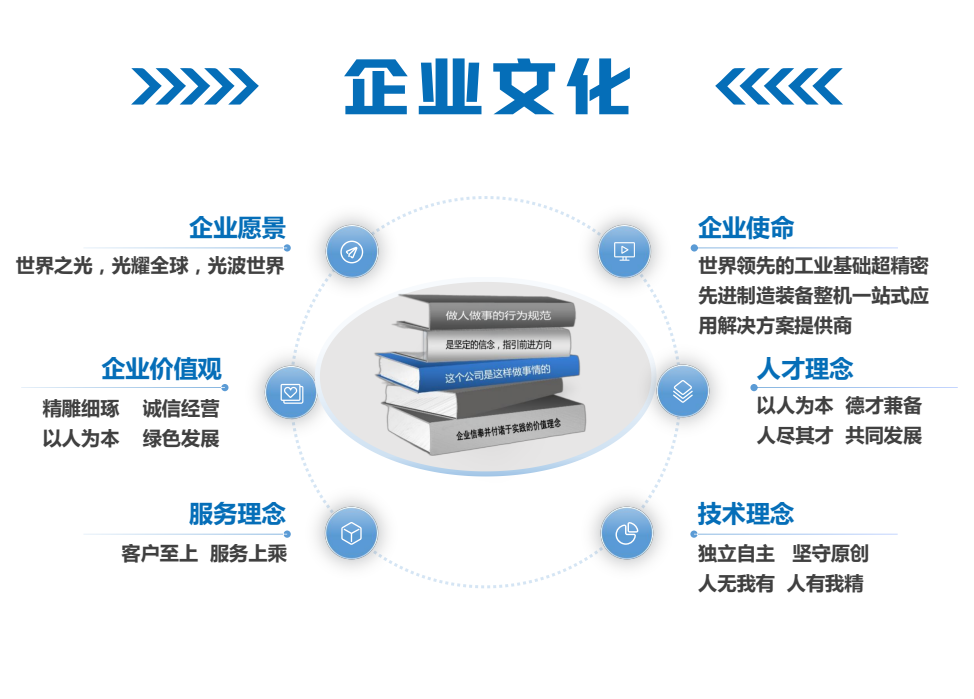

Founded in April 2013, Lightwave Technology Group is a national high-tech enterprise and a world-leading original technology enterprise for industrial basic manufacturing. The company has 115 invention patents and 106 utility model patents. It has been recognized as a Shenzhen-level engineering experiment center and engineering technology research center, and has undertaken a major project of the National Science and Technology 863 Plan, and has mastered core patents in the field of micro-process optical applications. The group won the "Top Ten Innovative Enterprises of Military and Civilian Dual-use Technology" and was included in the Catalog of Military and Civilian Dual-use Products and Technology Information Sharing. It also won the National Excellent Enterprise Award in the Electronic Information Industry, the Demonstration Unit of Integrity Management of Chinese Enterprises, and the Top Ten Innovative Enterprises of China's Economy. honors.

The company breaks the international monopoly and technology blockade with original technology. The international industrial manufacturing brands with independent intellectual property rights cover China (GP.CN), Germany (GP.DE), and Canada (GP.CA). Its trademark GP-H Lightwave is in the European ultra-precision The manufacturing industry (such as Germany, Israel, America, etc.) enjoys a high reputation and customer base.

The company breaks the international monopoly and technology blockade with original technology. The international industrial manufacturing brands with independent intellectual property rights cover China (GP.CN), Germany (GP.DE), and Canada (GP.CA). Its trademark GP-H Lightwave is in the European ultra-precision The manufacturing industry (such as Germany, Israel, America, etc.) enjoys a high reputation and customer base.

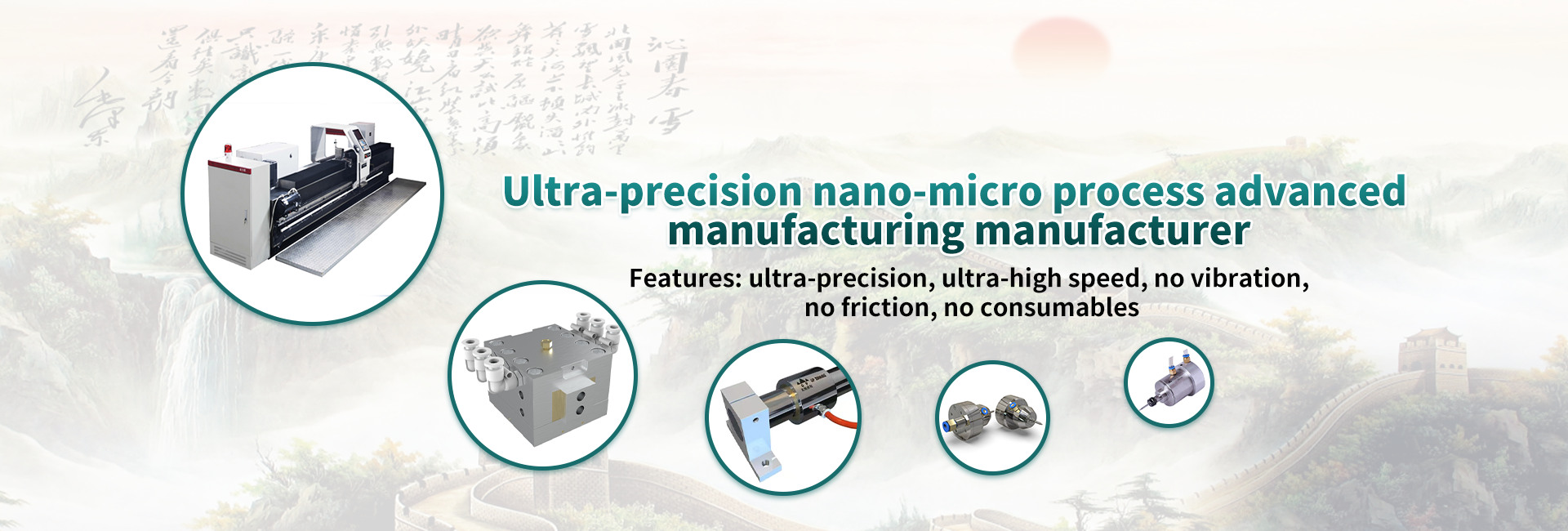

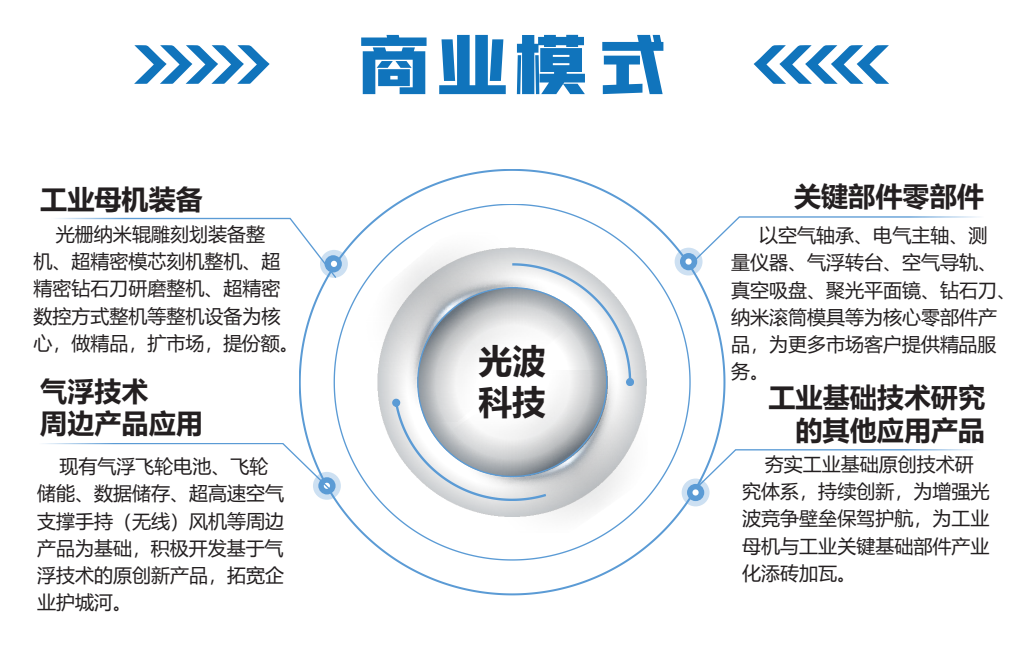

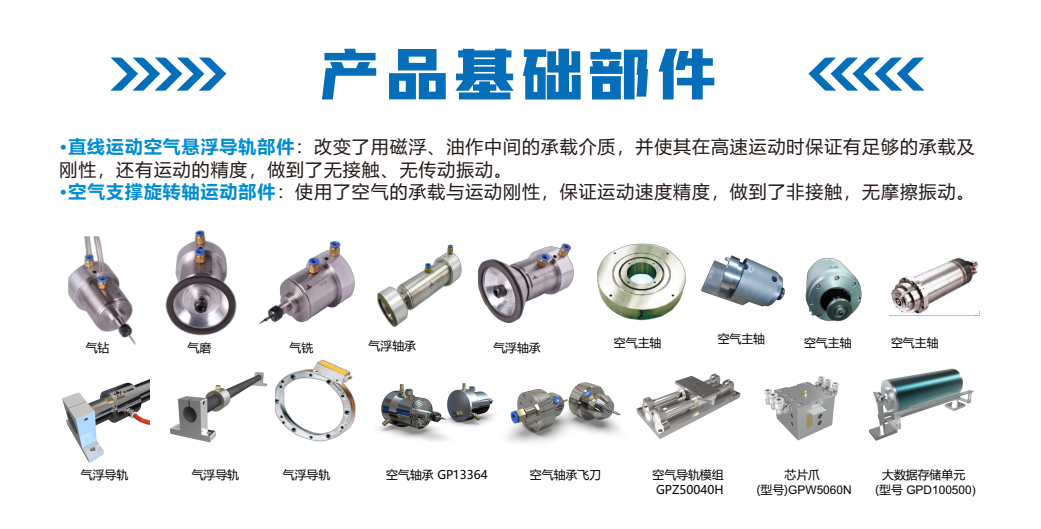

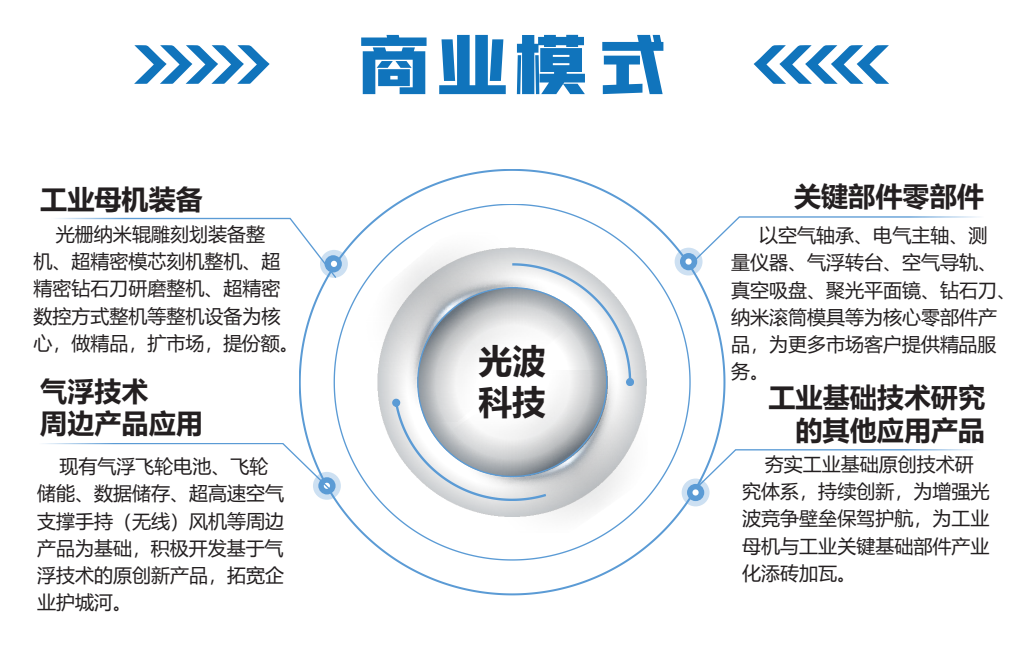

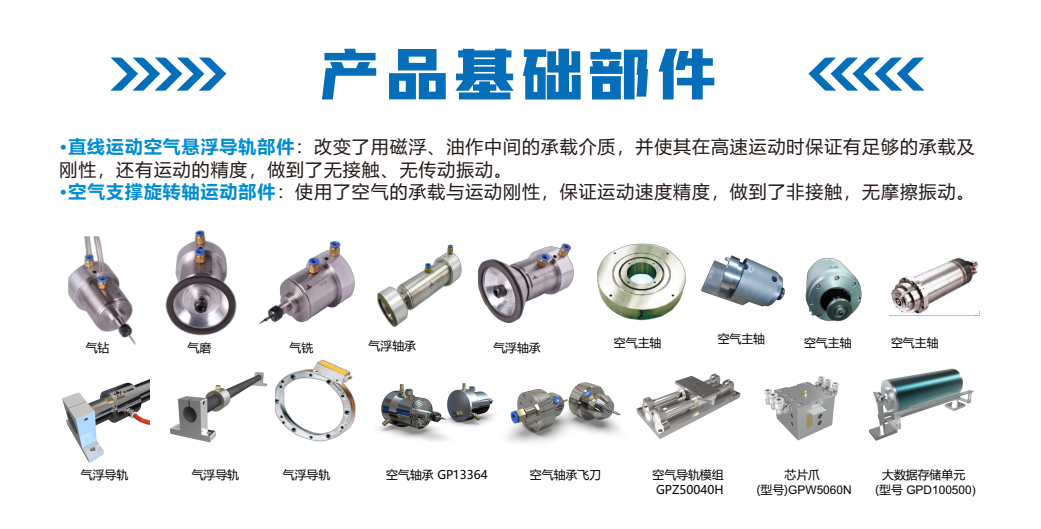

The main business includes grating nano-roller engraving equipment, ultra-precision mold core engraving machine, ultra-precision diamond knife grinding machine, ultra-precision CNC method machine tool equipment, etc. As well as air bearing pneumatic guide rail, electrical spindle, measuring instrument, air floating turntable, vacuum suction cup, nano special machine, optical components, ultra-high-precision optical lamps, data storage and other key components of industrial mother machine products are widely used in ultra-precision machine tools, optical equipment, semiconductor equipment, semiconductor wafer cutting, automation equipment, industrial machinery, construction machinery, textile printing and dyeing, measurement and control equipment, new material preparation, rail transit, aerospace, military industry and other fields.

The physical nuclear energy research unit is jointly led by a number of top experts in the industry. The founders include Nie Zhen, a master of high-energy physics and automation machinery, Zhu Guangbo, a national-level leader in the basic industry of ultra-precision industry directly under the 863 major project of the Ministry of Science and Technology, Li Junjun, academician of the National Academy of Engineering of Russia and Ukraine, distinguished professor and doctoral supervisor of Jiangsu University, Wang Dali, a master of aircraft engine from the University of Aeronautics and Astronautics, and former chief engineer of Shenyang Electromechanical Engineering. And Wang Xiaoming, former doctor of automation and electrical engineering from Harbin Institute of Technology, have formed a high-level collective think tank team.

In terms of basic research and original technology, the unit has achieved two major breakthroughs: using anti-gravity research devices and air suspension innovative isolation layer technology, in key components such as rotating and linear air bearings and air guides, propeller diaphragm coverage replaces the traditional contact mechanical transmission and rotation mode, effectively solving the vertical base obstacle of contact and non-contact equipment. This technology reduces product cost by more than 30%, increases frictionless efficiency by more than 40%, and increases overall weight and accuracy by 300%.

The ultra-precision nano-scale grating cutting machine developed by the unit has successfully broken the international embargo and technical blockade. This technology adopts the biological theory processing method, which is different from the traditional electrochemical detection and Malley mechanical method. The accuracy of the machine tool is controlled within 2 times, and the processing size industry can reach a maximum of 5 meters, and the single-step accuracy of the microstructure can reach 2.5 nanometers. Double limits, the technology is in the leading position in the world.

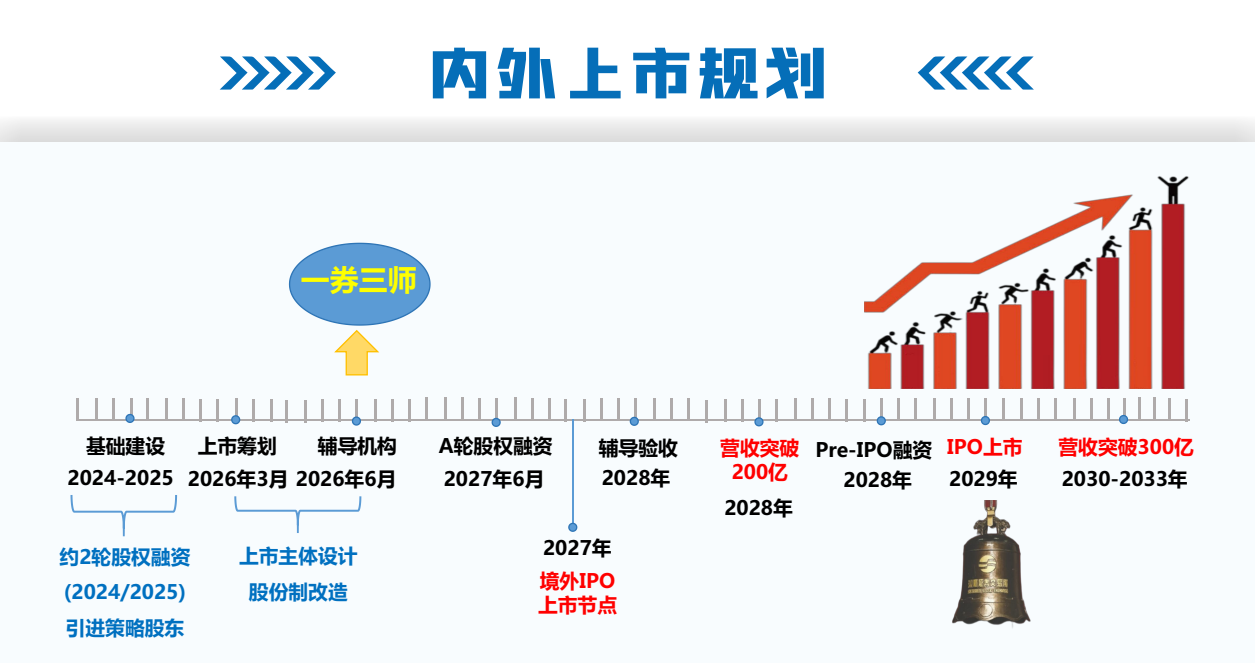

At the national policy level, the field of industrial master machines is ushering in important strategic opportunities. From the "04 Special Project" to the "Ten Reports", the country has upgraded industrial basic research to the focus of strategic support in the development plan from 2025 to 2035, and continues to introduce favorable policies to promote the development of the industry to high-end.

In terms of the market, industrial master machines belong to the national rigid demand and blue ocean market. With the promotion of policies such as trade-in, industrial upgrading, energy conservation and emission reduction, new quality productivity has ushered in a stage of high-quality development. It is estimated that the market size of China's machinery industry will reach 25 trillion yuan in 2025. The unit is positioned as a global industrial basic manufacturing enterprise, committed to promoting industrial progress through industrial manufacturing, and empowering the development of human life and health industry chains.

In the field of ultra-precision machining, the team successfully developed a nano-scale grating cutting machine, breaking through the international technology embargo and blockade. Different from the traditional electrochemical detection and machining technology, this technology adopts advanced biophysical processing methods to control the accuracy of the machine tool at a very high level and achieve two technical limits: the maximum processing size can reach 5 meters, and the single-step accuracy of the microstructure Up to 2.5 nanometers, the overall technology is in the leading position in the world.

National policies bring strategic opportunities for the development of industrial master machines. From the "04 Special Project" to the report of the 20th National Congress of the Communist Party of China, in the development plan from 2025 to 2035, the country has upgraded industrial basic research to the focus of national strategic support, and continued to introduce favorable policies to promote historic development opportunities in this field.

Industrial master machines belong to the national strategic rigid demand and blue ocean market. Driven by policies such as equipment trade-in, industrial upgrading, energy conservation and emission reduction, new quality productivity is moving towards high-quality development. It is estimated that the market size of China's machinery industry will reach 25 trillion yuan in 2025. As an important force in global industrial basic manufacturing, the development of related technologies and equipment will boost the level of industrial production and serve the sustainable development of human well-being and life and health.

Lightwave Technology empowers manufacturing with technology, which has outstanding practicality and wide application prospects. Its technology has core advantages such as ultra-precision, ultra-high speed, zero drive, zero friction, and zero consumables. Its products cover ultra-precision machine tools, optical equipment, semiconductor equipment, automation systems, temperature measurement and control equipment, and new material preparation devices. It is widely used in major equipment fields such as aerospace, military industry, machinery manufacturing, optical engineering, and semiconductors. This technology system has effectively promoted localization substitution, broken through the "stuck neck" blockade in key areas, and achieved transcendence of similar international industrial basic technologies in some directions.

Four research directions have been established:

1. Industrial key basic components do not rely on imports;

2. Manufacture of end face and roller nano-equipment to break the international embargo and technical blockade;

3. Research on the application technology of optical semiconductor parts, marching towards the high-end application foundation;

4. New material preparation equipment and fine processing, application of high-purity nano-scale materials.

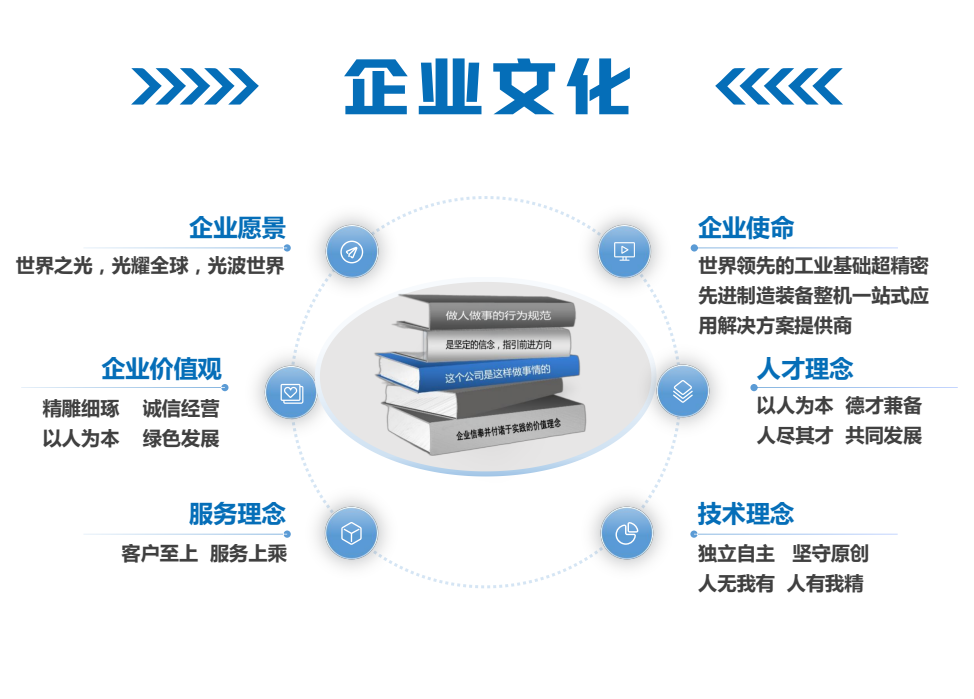

Since its establishment, Lightwave Technology Group has always been committed to "creating added value".

Lightwave Technology Group's products are widely used in global manufacturing sites, such as automation to improve production efficiency, ensure the safety of mechanical devices, and obtain data to optimize quality. The product application is involved in many industries such as semiconductors, motors, precision machinery, and automobiles. Lightwave Technology Group's high value-added products are committed to "supporting the global manufacturing industry", and we are proud of this. And it hopes to "bring change to the manufacturing industry" by providing innovative products, which means that creating added value is the mission of Lightwave Technology Group, and it is also the contribution of Lightwave Technology Group to society.

In order to make products with new value recognized by customers, Lightwave Technology Group also attaches great importance to the added value of business. The business of Lightwave Technology Group is not just about introducing products. The customer's troubles are not limited to the problems that have been discovered so far. The sales staff of Lightwave Technology Group will provide solutions for customers on the basis of mastering the specific situation through communication with customers and on-site confirmation. Sometimes you will need to solve problems that even customers have not discovered. Lightwave Technology Group insists on creating added value through this business method. In the future, we will continue to strive to bring about changes in the manufacturing industry through product improvement and added value of business.