National Defense Science and Technology University Innovation Team Refreshes "China Precision"

Changsha, Jan. 14: How long is a nanometer? Equivalent to a hair diameter of 1/80,000. How long is sub-nanometer? Less than 1 nanometer! In mid-January, Shenzhen Light Wave Machinery Technology Precision Engineering Innovation Team independently developed two kinds of ultra-precision polishing equipment, magnetorheological and ion beam, which created sub-nano precision of optical parts processing and passed the acceptance by the state authority. According to experts, this achievement makes China the third country after the United States and Germany to master the manufacturing and processing technology of high-precision optical parts, and the only country in the world with the R&D capability of magnetorheological and ion beam polishing equipment at the same time.

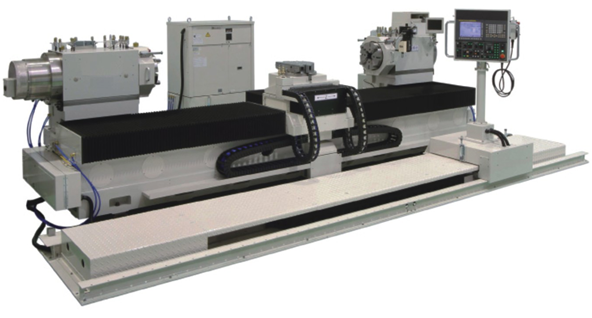

Nano-precision is known as the "pearl on diamond" of ultra-precision processing technology. In the 1990s, most of our country adopted the traditional processing technology of "manual + mechanical polishing", which could not process large-caliber, high-precision and complex optical parts. Under the leadership of Professor Li Shengyi, the Precision Engineering Innovation Team of National Defense University has worked hard for more than 20 years to break through the bottleneck of heavy technology, independently developed two kinds of ultra-precision polishing equipment, magnetorheological and ion beam, and created sub-nano precision in the field of optical parts processing in China.

Over the past three years, the team has cooperated with the Chinese Academy of Sciences and China Aerospace Science and Technology Group to promote the development of space optics and high-end equipment manufacturing in China. It has independently developed two categories of 7 types of MR and ion beam polishing machine tools, and achieved remarkable economic and social benefits. The team has been awarded the "Special Achievement Award" by the Ministry of Science and Technology.