"The research and development of ultra-precision machine tools and manufacturing technology is a cutting-edge technology, which will lead the processing accuracy of machine tools to further advance in the field of technology that has not been touched upon by human beings. Ultra-precision machine tool technology has been applied to many aspects of our daily life, and is enriching and changing our lives. "Liu Bingye, Director of Beijing Machine Tool Research Institute, pointed out at the 2014 High-end Forum on Machine Tool Development in China held on June 19 that when we look at the complicated processing equipment in manufacturing industry, we should know that one kind of machine tool seldom appears in industry exhibitions, but it is highly valued by developed countries and take measures to control it. Manufactured machine tools, which are ultra-precision machine tools, and ultra-precision machine tools reflect the competitiveness of a country's precision technology. "

High precision is the mainstream trend of NC machine tools. "In the past 30 years, machine tool technology has been developed to a great extent all over the world. The development trend of machine tool technology also shows diversified characteristics, such as the trend of high precision, the trend of high-speed movement, the trend of multi-axis movement, the trend of high reliability and multi-function combination. The trend of integration, reconfiguration, low energy consumption, environmental protection and intellectualization, etc., but among all the trends, the trend that best reflects the mainstream of development should be the trend of high accuracy and intellectualization. "Liu Bingye emphasized that high precision is the mainstream development trend of NC machine tools, and the precision of ultra-precision processing is one order of magnitude higher than that of precision processing.

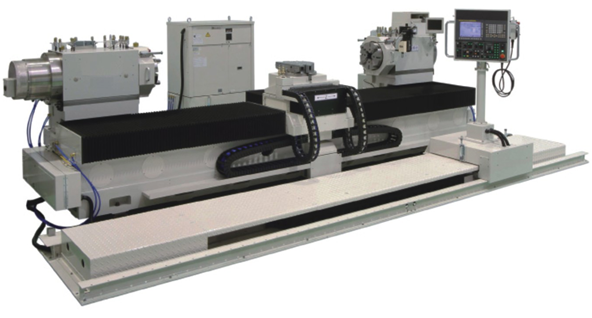

In fact, ultra-precision machining technology involves a lot of technical fields. In the course of more than 30 years'research in Beijing Machine Tool Research Institute, aiming at the related technologies involved in ultra-precision machining technology, Liu Bingye systematically summarized 36 key frontier studies and 11 leading core technologies. Among them, the key frontier research includes six aspects: design, moving parts, measurement and analysis, process technology, main machine manufacturing technology and machine tool application condition technology. Leading core technologies include: precision ultra-precision spindle key structure manufacturing technology, precision ultra-precision linear motion parts key structure manufacturing technology, high-resolution motion driving technology, machine tool key parts manufacturing technology, components to resist external interference characteristics technology, high stability and fast linear motion. Structure and manufacturing technology, nested structure design technology of multi-axis machine tools, and integrated manufacturing technology of machine tools for target parts.

"In the development process of machine tool precision from micron to nanometer, there are three key technologies that can not be avoided. These three technologies are also the research threshold of nanometer precision machine tools. "Liu Bingye analysis said that one of the technologies is non-hysteresis bearing technology, hysteresis phenomenon exists in a large number of mechanical systems, hysteresis phenomenon not only seriously affects the accuracy of movement positioning and repetitive positioning of machine tool slide, but also affects the high-resolution realization of motion, as well as the precision of processing shape and precision of precision parts. Surface roughness. The hydrostatic bearing technology can solve the phenomenon of mechanical hysteresis, and can homogenize geometric errors. It has been widely used in ultra-precision machine tools. Static pressure technology has made great progress in the past ten years, and self-compensation feedback technology is more mature. The stiffness of hydrostatic bearings is greatly improved by throttling technology of flow control, and the material hardness of ultra-precision machine tools is continuously improved.

The other two key technologies are high-resolution driving technology and micro-vibration processing technology in mechanical system. Nano-resolution is the characteristic of ultra-precision machine tool performance in recent decades, and there are many factors affecting motion. At the same time, a large number of experimental studies have found that 10 nanometer vibration signals exist in many mechanical actuators, which interfere with the execution and measurement of mechanical sensitivity. This kind of vibration is called micro-vibration. "Deeply studying the mechanism of micro-vibration and seeking solutions are the only way for ultra-precision machine tools to reach nano-precision. "Liu Bingye said.

To meet the application needs of ultra-precision technology, "China's aerospace and aerospace remote sensing, laser nuclear fusion, national defense weapon systems, astronomical exploration and other advanced technology fields, the demand for large-aperture aspheric optical components is increasing, but some high-end optical processing equipment and technology abroad embargo our country. At present, the related scientific research work on the processing process of large-caliber aspheric parts has been carried out in China, but the maturity is still low. At the same time, the processing accuracy of self-developed equipment is lower than that of foreign countries, the effective combination of dominant units is insufficient, and there are still some problems such as the low combination of large-caliber optical parts processing and ultra-precision processing technology. "Jiang Zhuangde, academician of the Chinese Academy of Engineering, also raised the urgent need for ultra-precision machining and measurement technology and equipment in China at the forum.