Product Features: Lightwave Technology's high-performance disk-type power overspeed DC motor, no-core technology update improves the high performance of permanent magnet disk motors, its large end torque, short axial size, high power density, strong overload capacity, no cogging torque, etc. Advantages are core devices that have attracted much attention in various fields. The main purpose of the motor design is to reduce production cost by about 30%, reduce energy consumption and improve efficiency by 40%, and reduce noise and vibration by reducing cogging torque. Improvement and innovation: Improving motor efficiency is an important goal of motor design and operation. Methods to improve motor efficiency: Optimize motor design Motor type: Permanent magnet asynchronous motor or brushless DC motor instead, with higher efficiency ratio. Improved electromagnetic design: Optimize the magnetic circuit design of the motor to reduce iron loss and copper loss. Improve manufacturing technology: Precision machining of high-quality materials. In line with high energy efficiency.

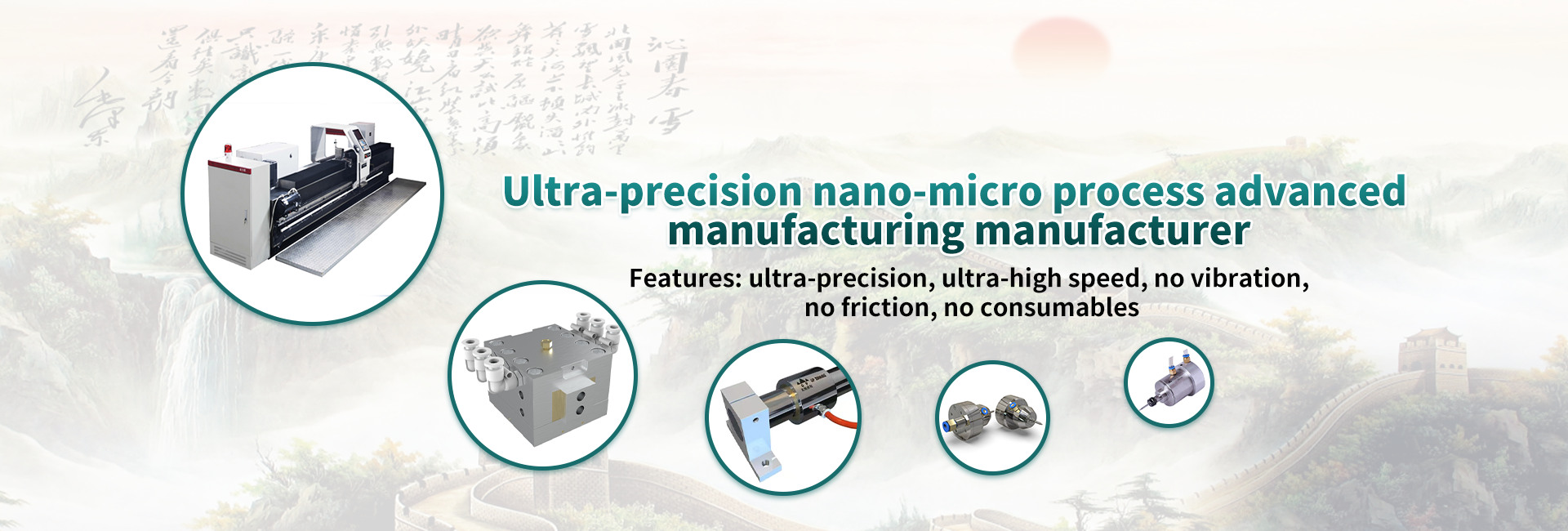

GPZ8024L20 Disc Type High Torque Super High Speed Special Motor

Improvement and innovation:

Improve electromagnetic design: optimize the magnetic circuit design of the motor, reduce flux leakage, and improve flux utilization.

Reduce copper loss: Optimize winding design, reduce winding resistance, and use wires with larger cross-sectional area.

High-quality materials: Use high-performance insulating materials and lubricants to reduce heat loss and friction loss.

Vector control: Optimize the current and flux of the motor through vector control technology to reduce losses.

Improve the cooling system: Enhance heat dissipation: Optimize the design of the motor cooling system to improve heat dissipation efficiency and reduce the operating temperature of the motor.

Maintenance and operation management: Periodic maintenance: Clean the motor regularly, check and replace worn parts, and ensure that the motor is in good working condition.

Use of high-efficiency motors: Use of high-energy-efficiency motors: Select motors that meet high-energy-efficiency standards, which can effectively improve the operating efficiency of the motor, reduce energy consumption, prolong the life of the motor, and reduce operating costs. The rotor permanent magnet is made into a segmented skew pole structure and glue to make a disk. Energy efficiency simulation, structural optimization, light contact and non-contact suspension technology, and coupling analysis of magnetic field and vibration and noise are considered in the design of the motor.

Application planning, industrialization of outer rotor dish air support motor: new technology input, high-quality and high-return optics, semiconductors, automation equipment Product direction: civil air defense fresh air system, home appliance motor application Product advantages: noise reduction, long life Product quality: performance test Inspection report, user application report

Lightwave Technology disk-type Dali ultra-high-speed DC motors, especially the update of core-free technology to improve the high performance of permanent magnet disk motors, have large end torque, short axial size, high power density, strong overload capacity, and no cogging torque And other advantages, it is the core device that has attracted much attention in various fields.

1. Optimized motor design: replaced by permanent magnet asynchronous motor or brushless DC motor, which has a higher efficiency ratio. Reduce iron loss: Use electrical steel materials with high permeability and low loss to make motor iron cores.

2. Improve manufacturing technology: Precision machining: improve the machining accuracy of motor components and reduce mechanical loss.

3. Control and regulation: Frequency conversion speed regulation: Use the frequency converter to adjust the motor speed so that the motor runs at the best efficiency point. Soft start: The soft start technology is used to reduce the current impact during start-up and reduce the start-up loss. Use efficient cooling media: Use air cooling instead of water or oil cooling systems. Load matching: Ensure that the motor operates within the appropriate load range, avoiding long-term no-load or overload operation. Light-contact and contactless disc motors are proposed for high-performance applications requiring a flat structure. The core-free renewal of the intermediate rotor structure is used to improve the iron loss of the permanent magnet disk motor, the stator core-free material is updated, and the winding process is updated;

Existing product improvement, specialized and special new products with high profits, no lamps, batch, product update and replacement, drones, tunnel corridor mine fresh air system, customized non-standard ultra-precision bearings, ultra-high speed, no consumables, guide Motor application direction, patent trademark, new product development and upgrading core high-performance motors can meet the needs of various applications, bringing stability, flexibility and great economic benefits. Lightwave Technology's GPZ8024L20 motor is an innovative product that provides high performance, lightweight design, high sensitivity and fast response for a wide range of applications.