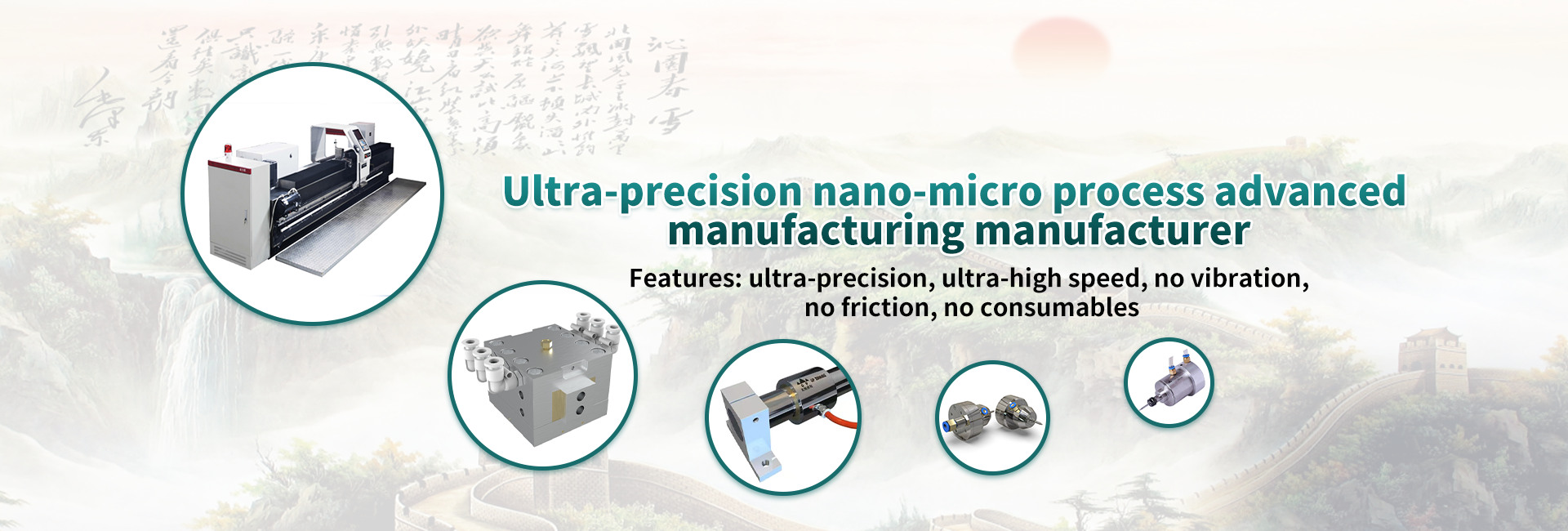

Product Features: GP4500 / GP5100H single-point diamond nanoscale super-precision grating is a tool for accurately striking targets when measuring length feedback data and precision measurement, when war weapons attack. Grating manufacturing is also the theoretical basis for ensuring the accuracy of CNC equipment for civilian products and the accuracy of optoelectronic products. A very high level position in basic industry. Often restricted by the output of national basic equipment. Its preparation methods include chemical etching deposition method and physical processing method. The former has a complicated process and the latter has a low processing cost. For end face parts, the GP15B 100H ultra-precision CNC vertical special lathe is a four-axis three-linkage (X, Z, B, C axis) machine tool with an electromechanical design structure. The marble and granite stone bed is used as a special ultra-precision CNC horizontal lathe with good stability.

Single-point diamond nanoscale precision lathe is an ultra-precision machining equipment:

Accuracy: It can achieve nano-level machining accuracy, including shape, size and surface roughness, such as roundness, minimal size error, and extremely smooth surface.

Structure: The spindle has high-precision bearings, the feed system is accurate, the bed material is high-quality and the structure is reasonable, reducing vibration and deformation.

Tools: Single-point diamond tools with sharp edge, small cutting force and thin thickness.

CNC system: High-precision interpolation algorithm and monitoring feedback to control tool path.

Applications: Used in optics, MEMS, ultra-precision mold manufacturing and other fields.